Single Twin

SINGLE or TWIN FLYING CUT-OFF

The cutting process of single or twin flying cut-off applications is critical in high-speed steel processing for precise and efficient cutting of rolled or directly formed materials such as tubes and profiles. The flying cut-off sawing machines operate by synchronizing the cutting unit with the moving profile or tube, making a clean and accurate cut without interrupting production flow.

A regular single flying cut-off machine operates with one circular saw blade to cut tubes and profiles. A twin version with two saw blades offers faster cutting times, enabling the entire tube line to run at higher line speed. This process utilizes specially designed High Speed Steel (HSS) saw blades Tungsten Carbide Tipped (TCT) or Tungsten Carbide Tipped (TCT) saw blades for increased efficiency. By cutting tubes with the right saw blade, the processing time will be reduced and blade life will be long which enhances overall productivity.

Common applications of Single or Twin Flying cut-off

Single and twin flying cut-off applications are essential in industries requiring high-speed, precise cutting of steel tubes and profiles. They are widely used in steel tube manufacturing, mechanical engineering, the automotive industry (exhaust pipes, chassis, hydraulic tubing), construction (scaffolding, railings, structural tubes), and oil & gas (pipeline tubing, drill pipes, casing tubes). They also play a key role in furniture, appliances, consumer goods, aerospace, and renewable energy for cutting steel frames, structural components, and lightweight materials.

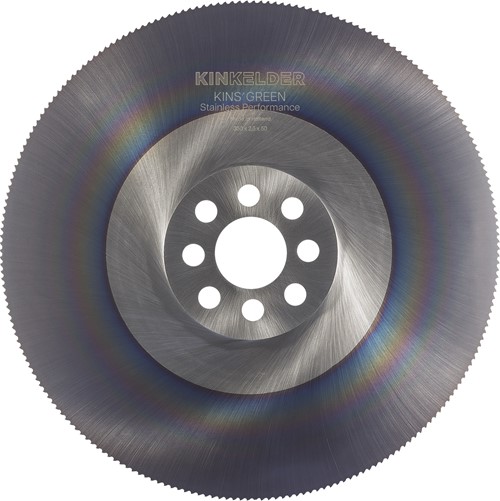

DISCOVER OUR TCT AND HSS SAW BLADES FOR SINGLE TWIN FLYING CUT-OFF

In the KINS’ ORANGE and KINS’ GREEN product ranges, KINKELDER offers dedicated saw blades for single or twin cutting of steel tubes or pipes.